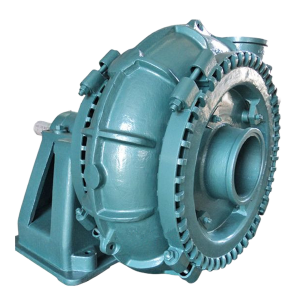

I-TSP / TSPR vertical Slurry Pump

I-TSP / TSPR vertical Slurry PumpYenzelwe izinhlelo zokusebenza ezidinga ukwethenjwa okukhulu nokuqina kunamaphampu wenqubo evamile mpo anganikela. I-elastomer egcwele ngokugcwele noma insimbi enzima yenziwe. Ayikho imithwalo engaphansi noma ukupakisha. Design ephezulu yokumunca kabili. Ubude obungeniswe ngokwezifiso nokumisa amandla atholakalayo. Ipompo ye-TSP / TSPR vertical mpo yempompo efanelekile efanelekile yokuphathwa okuqhubekayo okuqhubekayo koketshezi olungenamsoco kanye nokuncipha ngenkathi kufakwe izigaxa noma emigodini.

Izici Zokwakhiwa

√ Ukugqoka okuncane, ukugqwala okuncane

Izakhi ezimanzi zitholakala ezinhlobonhlobo zama-alloys nama-elastomers, lapho amaminerali e-weir akhetha inhlanganisela enkulu yezinto zokumelana kakhulu ukuze ugqoke noma yisiphi isicelo se-abrasion, kufaka phakathi ukumelana nokugqwala okuphezulu nalapho kuhlangana khona izinhlayiya eziphakeme.

• Ukumelana nokumelana ne-abrachrome® alloy.

• I-Abrasion / Cororion-Relistrant A49 Hyperchrome® Alloy.

• Izinsimbi ezingavikeleki kakhulu ezingenacala.

• Ama-elastomers wemvelo nakwenziwa.

Alikho ukwehluleka okuphambaniswa okuphansi

Umgodi we-cantilever we-robust ugwema isidingo semibuthazo ephansi ephansi - okuvame ukuba ngumthombo wokuhluleka ukuthwala ngaphambi kwesikhathi.

• I-Heavy Duty Roller Bearrings, ngaphezulu kwe-fundingplate.

• Azikho izibopho ezingaphansi.

• Ukuvikelwa kweLabyrinth / Flinger ephethe.

• Shaft eqinile, enkulu.

Azikho izinkinga zokubopha uphawu

Umklamo we-cantilever mpo akadingi sendi kaShaft.

√ Akukho okudingekayo okudingekayo

Idizayini ephezulu nangaphansi ye-Inlet Ilungele izimo "ze-snore".

√ Ingozi encane yokuvimba

Ama-inlets ahloliwe kanye namavesi amakhulu ama-impeller anciphisa ubungozi bokuvinjelwa.

√ Izindleko zamanzi ezi-zero

Umklamo we-cantilever mpo ngaphandle kwe-gland noma amabheyili angaphansi komhlaba agwema isidingo se-gland ebizayo noma anikeze amanzi agcwele amanzi.

I-TSP / TSPRImpompo ethambile ye-slurryamapharamitha okusebenza

| Isifanekiso | Ukumatanisa amandla p (kw) | Amandla Q (M3 / H) | Ikhanda h (m) | Isivinini n (r / min) | Qhuma. (%) | I-Impeller Dia. (MM) | Max.Particles (MM) | Ubunzima (kg) |

| I-40PV-TSP (R) | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 40 | 188 | 12 | 300 |

| I-65QV-TSP (R) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | I-280 | 15 | 500 |

| I-100RV-TSP (R) | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | I-370 | 32 | 920 |

| I-150SV-TSP (R) | 11-110 | I-108-576 | 8.5-40 | 500-1000 | 52 | I-450 | 45 | 1737 |

| I-200SV-TSP (R) | 15-110 | I-180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | I-2800 |

| I-250TV-TSP (R) | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| I-300TV-TSP (R) | 22-200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

I-TSP / TSPRImpompo ethambile ye-slurryIzicelo

Amaphampu we-TSP / TSPR averical slurry atholakala ezinhlotsheni eziningi ezithandwayo ukuze avumelane nezicelo zokupompa eziningi. Amaphampu we-TSP / TSPR SUMP afakazela ukuthembeka kwawo kanye nokusebenza kahle komhlaba wonke ku: Ukulungiswa kwamaminerali, ukulungiswa kwamalahle, ukuphathwa kwe-effluen, isihlabathi kanye namatshe amatshe acishe kube yilowo nalowo ithangi elixakile. Idizayini ye-TSP / TSPP ye-TSPR eno-Hard Metal (TSP) noma i-Elastomer embozwe (ama-TSPR) enze ilungele ukuncipha okuhlangene futhi / noma okulimazayo, imisebenzi ephakeme kakhulu, imisebenzi eqhubekayo efuna imigodi ye-cantilever.

* Amaphampu we-tsp mpo mpo athambile kanye nezindawo eziguqukayo kuphela eziguqukayo ngamaphampu we-bafan® sp ve vertical slurry kanye nezindawo.

Th cantileverever, enezingqimba, centrifugal slurry pump tampu:

| Ikhodi Yezinto Ezibonakalayo | Ukuchazwa Kwezinto Ezibonakalayo | Izingxenye zohlelo |

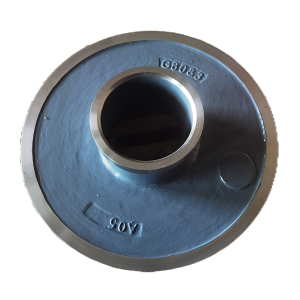

| A05 | 23% -30% CR WHITE IR WHITE | I-Impeller, ama-liners, expeller, indandatho yokuxoshwa, ibhokisi lokugxusha, umthungo, ifreyimu yeplate liner insert |

| A07 | 14% -18% cr white iron | Impeller, ama-liners |

| A49 | 27% -29% CR Carbon White Iron | Impeller, ama-liners |

| A33 | Ama-33% CR ukungenela & ukubhujiswa kwensimbi emhlophe | Impeller, ama-liners |

| R55 | Irabha Yemvelo | Impeller, ama-liners |

| R33 | Irabha Yemvelo | Impeller, ama-liners |

| R26 | Irabha Yemvelo | Impeller, ama-liners |

| R08 | Irabha Yemvelo | Impeller, ama-liners |

| U01 | Polyurethane | Impeller, ama-liners |

| G01 | Impango yensimbi | Ipuleti yohlaka, isembozo sepuleti, expeller, indandatho yokuxosha, indlu ethwala, isisekelo |

| D21 | I-rouctile iron | Ipuleti yohlaka, isembozo sembozo, indlu ethwala, isisekelo |

| I-E05 | Insimbi yekhabhoni | Umgodi |

| C21 | Insimbi engagqwali, 4crm13 | I-Shaft Sleeve, I-LANNN RIRIN, Isivikelo Sezibani, Indandatho Yentamo, I-Gland Bolt |

| C22 | Insimbi engagqwali, 304ss | I-Shaft Sleeve, I-LANNN RIRIN, Isivikelo Sezibani, Indandatho Yentamo, I-Gland Bolt |

| C23 | Insimbi engagqwali, 316ss | I-Shaft Sleeve, I-LANNN RIRIN, Isivikelo Sezibani, Indandatho Yentamo, I-Gland Bolt |

| S21 | I-Burty ruble | Izindandatho ezihlanganisiwe, izimpawu ezihlangene |

| S01 | Irabha le-EPDM | Izindandatho ezihlanganisiwe, izimpawu ezihlangene |

| I-S10 | Nitrile | Izindandatho ezihlanganisiwe, izimpawu ezihlangene |

| S31 | Ubuthonya | Impeller, ama-liners, indandatho yokuxoshwa, expeller, izindandatho ezihlanganisiwe, izimpawu ezihlanganyelwe |

| S44 / K s42 | -Eyrenu | Impeller, ama-liners, izindandatho ezihlanganisiwe, izimpawu ezihlanganyelwe |

| S50 | Iviyo | Izindandatho ezihlanganisiwe, izimpawu ezihlangene |