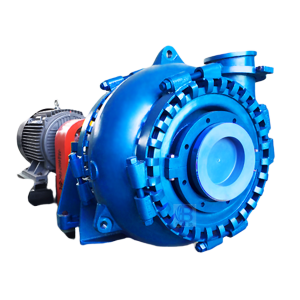

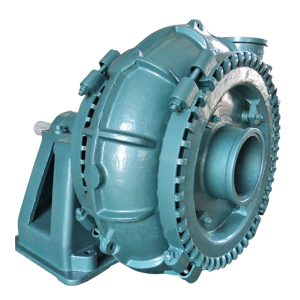

I-12 / 10G-TG Gravel Pump yoMfula uPumpeling Sand

Iphampu ye-12x10g-tg pumpYakhelwe ngqo ukupompa okuqhubekayo kokuhlambalaza okunolaka kakhulu, ngokusatshalaliswa kosayizi obukhulu. Iyakwazi ukuphatha izinhlayiya ezinkulu ngokusebenza kahle ngokungaguquki kuphumela ekubizeni okuphansi kobunikazi. Ivolumu enkulu yangaphakathi ye-casing inciphisa ama-velociaties ahlobene nokukhulisa impilo yezakhi. 12 × 10Ipompo yamatshe ama-sandIsetshenziselwa ukulethwa ukuhambisa i-slurry embizeni, isiqhumane esiqhuma ngokuncibilika kwensimbi, kubhejwa eDredger nasenkambeni yemifula neminye imikhakha.

Izici Zokwakhiwa:

• Imodeli ye-hydraulic ethuthukisiwe, umklamo we-CAD 3D, ukusebenza kahle kwamandla okusobala nokusindisa amandla asobala

• Ukujula kwesihlabathi esikhulu se-DEDEGG, ubuningi obuphezulu bodaka olwenziwe kahle, ipompo enhle ye-pump npsh kanye nekhono lokukhulisa elinamandla.

• Ukuqina ngokubekwa, iphampu elokwehlayo ingaqhubeka nokukhipha amatshe amatshe amatshe, inqwaba yenhlabathi ephezulu yeplastiki, njll.

• Isicelo esibanzi, iphampu yesihlabathi ingasetshenziswa ezinhlotsheni ezahlukahlukene zekhwalithi yenhlabathi.

• Iphampu yesihlabathi ye-G ingafaniswa ngqo nenjini kagesi noma injini yedizili.

• I-g pump ye-pump ye-G Impeller iyi-3 noma engu-5 yenqwaba yezinhlayiya ezinkulu ezilethwa.

• Ukulahleka okuncane kwe-hydraulic, ukusebenza kahle kakhulu kanye nokusetshenziswa kukawoyela okuphansi.

• Ukusebenza okuqhubekayo, ukudlidliza okuncane, umsindo ophansi.

• Ukwakhiwa okulula nokwethembekile, ukungafani kalula kanye nomhlangano, ukulondolozwa okulula.

• Ukubekwa uphawu okuthembekile ngaphandle kokuvuza.

• Ukuphila isikhathi eside kwezingxenye zokugqoka.

I-12 / 10G-TG Gravel pump Pump Park Parameter

| Isifanekiso | UMax. Amandla p (kw) | Amandla Q (M3 / H) | Ikhanda h (m) | Isivinini n (r / min) | I-EFF. η (%) | Npsh (m) | I-Impeller Dia. (MM) |

| 12x10g-TG | I-600 | I-360-1440 | I-10-60 | 400-850 | 65 | 1.5-4.5 | I-667 |

I-12x10g-TG DREDGING SAND SHINT SHATH SHAFT Ilungiselelo

• Ukupakisha Seal kuyinto esezingeni eliphakeme se-shaft.Isebenza ezimeni ezahlukahlukene zokupompa, i-PTFE kanye nezinto zokwenziwa ze-graphinal zokupakisha zingasetshenziswa ezindaweni eziphakeme ezilonakalisayo noma izimo zokushisa eziphakeme.

• I-Depeller Seal i-Impeller Force yamandla we-centrifugal abuyiselwe emuva, ukuvimbela ukuvuza okumnandi. I-Expeller seal ingasetshenziswa ephampu yesiteji eyodwa lapho ingcindezi enhle yokungena kwephampu ingekho ngaphezulu kwe-10% yempumputhe yokuphuma kwepompo noma ethempelweni lokuqala ochungechungeni lwepompo.

• I-Mechanical Seal iyindlela ethuthukisiwe yokuvalwa uphawu ngaphandle kokuvuza uphawu, ukuhlanganisa ukwakhiwa, ukufakwa okulula nokubuyiselwa, ukwakhiwa okuhlukahlukene, isudi ehlukahlukene yazo zonke izinhlobo zemibandela.

12 / 10G-TGIphampu yamatsheIzinja

• Imayini: Imayini emnyama, engathandeki ye-ore ye-slurry yezinto ezibonakalayo nazo zonke izinhlobo zokugxila nokuqondisa ama-taillings.

• I-Metallurgy: Ukuhambisa ama-slurry ahlukahlukene we-aluminium noma ekwenziweni kwensimbi.

• Amalahle: Ukugezela kwamalahle, ukugeza kanye nokuhamba okuhlukahlukene okuhlanganisiwe kanye nokuhamba kwamalahle amalahle.

• Ugesi: Susa i-Power Plant Ash, Geza umlotha, ama-ash dregs ahlukahlukene noma ukuthuthwa komlotha.

• Izinto zokwakha: I-Slurry ehlukahlukene ye-MUD (enjengesimende Slurry) ezokuhamba.

• Amakhemikhali: Umanyolo we-phosphatic noma umanyolo we-potassic womanyolo efektri ehlukahlukene yokuhamba ye-slurry.

• Amanzi Conservanicy: Ichibi, i-River Driver, Sediment, Grit, Light Plastic Clay Plastic Umugqa wokuhambisa izinto.

Qaphela:

12 × 10 I-G-TG Amaphampu we-Gravel nama-Spares ayelapha kuphela ngamaphampu we-warran® 12 × 10 gG amaphampu nama-spares.

Th cantileverever, enezingqimba, centrifugal slurry pump tampu:

| Ikhodi Yezinto Ezibonakalayo | Ukuchazwa Kwezinto Ezibonakalayo | Izingxenye zohlelo |

| A05 | 23% -30% CR WHITE IR WHITE | I-Impeller, ama-liners, expeller, indandatho yokuxoshwa, ibhokisi lokugxusha, umthungo, ifreyimu yeplate liner insert |

| A07 | 14% -18% cr white iron | Impeller, ama-liners |

| A49 | 27% -29% CR Carbon White Iron | Impeller, ama-liners |

| A33 | Ama-33% CR ukungenela & ukubhujiswa kwensimbi emhlophe | Impeller, ama-liners |

| R55 | Irabha Yemvelo | Impeller, ama-liners |

| R33 | Irabha Yemvelo | Impeller, ama-liners |

| R26 | Irabha Yemvelo | Impeller, ama-liners |

| R08 | Irabha Yemvelo | Impeller, ama-liners |

| U01 | Polyurethane | Impeller, ama-liners |

| G01 | Impango yensimbi | Ipuleti yohlaka, isembozo sepuleti, expeller, indandatho yokuxosha, indlu ethwala, isisekelo |

| D21 | I-rouctile iron | Ipuleti yohlaka, isembozo sembozo, indlu ethwala, isisekelo |

| I-E05 | Insimbi yekhabhoni | Umgodi |

| C21 | Insimbi engagqwali, 4crm13 | I-Shaft Sleeve, I-LANNN RIRIN, Isivikelo Sezibani, Indandatho Yentamo, I-Gland Bolt |

| C22 | Insimbi engagqwali, 304ss | I-Shaft Sleeve, I-LANNN RIRIN, Isivikelo Sezibani, Indandatho Yentamo, I-Gland Bolt |

| C23 | Insimbi engagqwali, 316ss | I-Shaft Sleeve, I-LANNN RIRIN, Isivikelo Sezibani, Indandatho Yentamo, I-Gland Bolt |

| S21 | I-Burty ruble | Izindandatho ezihlanganisiwe, izimpawu ezihlangene |

| S01 | Irabha le-EPDM | Izindandatho ezihlanganisiwe, izimpawu ezihlangene |

| I-S10 | Nitrile | Izindandatho ezihlanganisiwe, izimpawu ezihlangene |

| S31 | Ubuthonya | Impeller, ama-liners, indandatho yokuxoshwa, expeller, izindandatho ezihlanganisiwe, izimpawu ezihlanganyelwe |

| S44 / K s42 | -Eyrenu | Impeller, ama-liners, izindandatho ezihlanganisiwe, izimpawu ezihlanganyelwe |

| S50 | Iviyo | Izindandatho ezihlanganisiwe, izimpawu ezihlangene |